Customized gummies, chocolates, or other candies and edibles can be a big boost for your business.

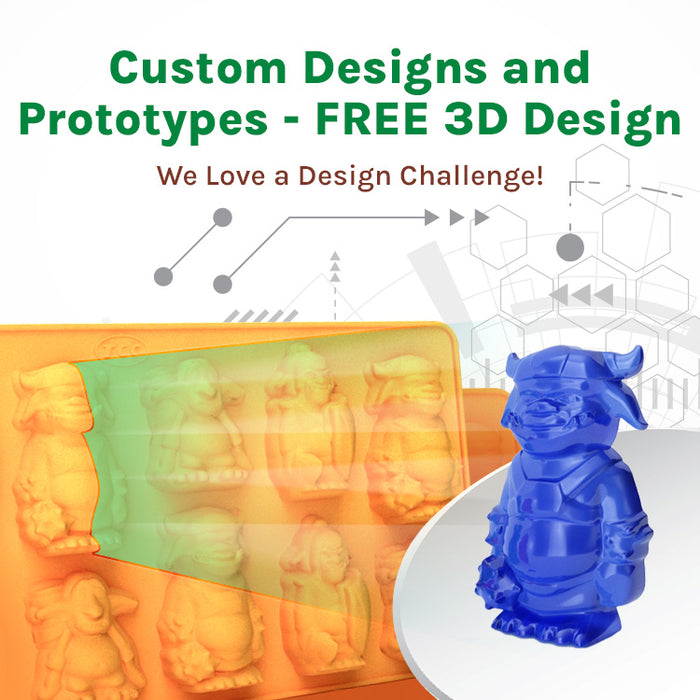

PJ Bold is the leading candy mold designer and manufacturer, serving several of the industry’s biggest candy companies. We create molds for consumers and wholesalers, as well as custom molds for businesses such as your own.

PJ Bold will help you drive demand with your own original candies, and we make it simple to design molds that are uniquely yours. Our staff will walk you through our simple process, involving you at every step.

Our design and manufacturing system for custom silicone molds will bring your edible candy visions to reality.